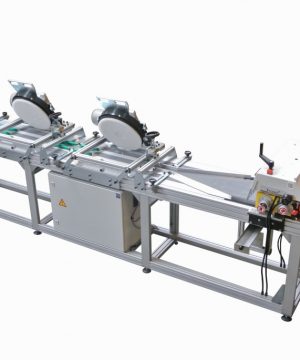

Type SL – HPR3

Clamps for edge gluing

The press is intended for a small work shops for a small quantity. It is also intended for edge gluing and lamination of wooden stock whose joints are dried naturally. It is very simple to maintain and to operate.

Pressing is carried out by hydraulic cylinders. The bottom stop is fixed and in one piece. The aligning units are driven manually from the working areas on each sided of the press prior to the loading of work pieces. Each aligning unit has 1 hydraulic cylinder. These cylinders allow a force of 1.4N per each aligning unit. Running rail is extended on one side of the press, so the unit can be moved. Steering is done by manual hydraulic valves.

TECHNICAL DATA

| Operating length | 2500 – 4000 mm |

| Operating height | 800 – 1200 mm |

| Operating thickness | 25 – 100 mm |

| Number of working side | 3 |

| Number of hydraulic cylinder per side | 5 – 8 |

| Specific pressure | 4,5 – 7 kg/cm2 |

| Number of aligning units per side | 2 – 4 |

| Parking place for aligning units on one side |