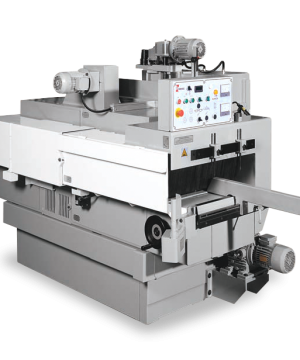

CENTRE DE PRELUCRARE CU COMANDA NUMERICA COSMEC CONQUEST 3200-4200-5200-6200

- MIX PERFECT INTRE ROUTER SI MASINA DE GAURIT PUNCT CU PUNCT

- Una dintre caracteristicile principale ale acestei mașini este cadrul deschis (consola), care permite încărcarea și descărcarea pieselor de dimensiuni mari foarte ușor. Mai mult, există posibilitatea de a echipa utilajul fie cu o masă de bakelită segmentata, fie cu un set de bare mobile și cupe cu vacuum. În ambele cazuri, grosimea panoului este de 300 mm. Această mașină este echipată cu o electromandrina de 7,5 kW și două magazii automate de scule: una tip carusel cu 8 poziții și una auxiliara, situata pe coloana cadrului, cu 2 sau 4 poziții, unde sunt disponibile toate agregatele unghiulare pe piața poate fi monta.

- CONFIGURAREA UTILAJULUI CONFORM CERINTELOR DE PRELUCRARE

- Pe langa electromandrina principala, masina poate fi echipata cu unitate independentă de gaurire (13 axe verticale independente, 4 axe orizontale pe axa X și 2 pe axa Y), o unitate mobilă cu motor de 2,2 Kw pentru frezare in plan orizontal cu una sau două guri de aspiratie, o unitate de retezare cu panza si motor de maxim 7,5 Kw cu una sau două guri de exhaustare si, ca alternativă, o a doua electromandrina cu magazie de scule. La cerere, electromandrina poate fi echipata cu o axă rotativă. Mașina este echipată cu un panou electric, un controler numeric OSAI seria 10, interfață Windows și telecomanda.

| DATE TEHNICE | 3200 | 4200 | 5200 | 6200 |

|---|---|---|---|---|

| Curse | X: mm. 3970 Y: mm. 1940 Z: mm. 520 |

X: mm. 4970 Y: mm. 1940 Z: mm. 520 |

X: mm. 5970 Y: mm. 1940 Z: mm. 520 |

X: mm. 6970 Y: mm. 1940 Z: mm. 520 |

| Camp de lucru | mm. 3200 x 1300/1800 | mm. 4200 x 1300/1800 | mm. 5200 x 1300/1800 | mm. 6200 x 1300/1800 |

| Grosime max panou la alimentare | mm. 300/500 | mm. 300/500 | mm. 300/500 | mm. 300/500 |

| Viteza vectoriala | 110 mt/m | 110 mt/m | 110 mt/m | 110 mt/m |

| Turatie | 500/24.000 rpm | 500/24.000 rpm | 500/24.000 rpm | 500/24.000 rpm |

| Putere electromandrina (S1) | Kw. 7,5/10/13,5/15 | Kw.7,5/10/13,5/15 | Kw. 7,5/10/13,5/15 | Kw. 7,5/10/13,5/15 |

| Adaptor de scule | ISO 30 – HSK F63 | ISO 30 – HSK F63 | ISO 30 – HSK F63 | ISO 30 – HSK F63 |

| Magazie de scule (pozitii) | N° 8 | N° 8 | N° 8 | N° 8 |

| Magazie de scule suplimentara (pozitii) | N° 4/12/20 | N° 4/12/20 | N° 4/12/20 | N° 4/12/20 |

| Putere invertor | Kw. 11/15 | Kw. 11/15 | Kw. 11/15 | Kw. 11/15 |

| Capacitate pompa de vacuum | 100 / 250 / 500 mc/h | 100 / 250 / 500 mc/h | 100 / 250 / 500 mc/h | 100 / 250 / 500 mc/h |

| Comanda numerica | OSAI seria 10 | OSAI seria 10 | OSAI seria 10 | OSAI seria 10 |

| Date de instalare | 3200 | 4200 | 5200 | 6200 |

| Putere maxima absorbita | Kw. 35 | Kw. 35 | Kw. 35 | Kw. 35 |

| Presiune de lucru | 6 bar | 6 bar | 6 bar | 6 bar |

| Cupla aer td> | G 3/8″ | G 3/8″ | G 3/8″ | G 3/8″ |

| Diametru gura exhaustare | Ø mm. 200 | Ø mm. 200 | Ø mm. 200 | Ø mm. 200 |

| Consum aer | 2650 mc/h | 2650 mc/h | 2650 mc/h | 2650 mc/h |

| Greutate si gabarit | 3200 | 4200 | 5200 | 6200 |

| Greutate | 5870 Kg. | 6420 Kg. | 7130 Kg. | 8080 Kg. |

| Dimensiuni de gabarit | mm. 5700 x 2320 x 2450 | mm. 6700 x 2320 x 2450 | mm. 7700 x 2320 x 2450 | mm. 8700 x 2320 x 2450 |